Product Name: Transglutaminase Sinzym TG100

• Increases mechanical strength and production yield

• Bondes meat pieces & surimi products

• Improves water-holding ability

• Improves temperature resistance

• Improves the texture and bit feeling

• Replaces or reduces phosphate

Enzyme: Transglutaminase Preparation

Synonyms: Transglutaminase, protein-glutamine γ-glutamyltransferase, TG, TGase

CAS#: 80146-85-6

IUB#: 2.3.2.13

Appearance: White to light brown powder

Souring Origin: Streptoverticillium mobaraense

Application: Yoghurt, Cheese, Flour and dough Strengthener, Bread improver, Flour treatment; Flour Improver

Total Aerobic Plate Count: 10,000 CFU/G max

Coliforms: 30 MPN/G max

Escherichia Coli in 25 g: None Detected

Salmonella in 25g: None Detected

Antibiotic activity: None Detected

Description:

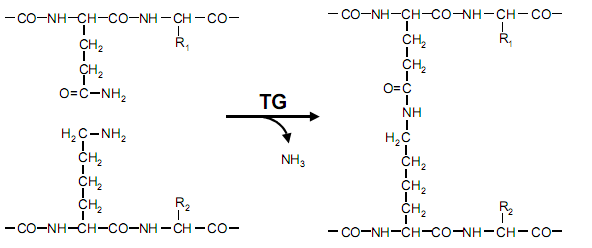

Transglutamianse (protein-glutamine γ-glutamyltransferase, EC 2.3.2.13) is a strong protein cross-linking (connecting residues of the amino acid L-glutamine to the amino acid L-lysine) enzyme preparation specialized for using in modifying proteins and offering great benefits for meat products. The product is produced by fermentation with a selected strain of a microorganism.

Usage rate:

The recommended dose rate is usually 50-500 ppm, but it could be optimized in the different material or production process (within a different temperature, pH and processing time).For frozen dough application, normally 100-400ppm. For dairy application, Yogurt-set during 80-330 ppm (Mid-east area case 100-120ppm); Yougurt-stirred during 120-500ppm (India area case 120-190 ppm); Cheese during 25-500 ppm.

For meat application, 100-150g have to be mixed with 100 kg of the meat raw material, hold for a few minutes or several hours (depends on dosage and temperature) at 5-50 °C. Dramatically improved effects are obtained with the addition of 500 to 1000 g sodium caseinate per 100 kg raw meat together with the enzyme. In some cases up to 3 kg sodium caseinate per 100 kg raw meat further increases binding strength and firmness. If caseinate added together with the TG sodium chloride is not necessarily need. Nevertheless a dosage of up to 3 kg improves binding in restructured meat. Without caseinate addition sodium chloride is needed to partially dissolve the meat surface for the release of free protein ends, which react with the transglutaminase.

Application range:

The product reaction is controlled by time and temperature. Lower reaction temperatures require longer reaction times. Higher reaction temperatures require shorter reaction time. Enzyme will be inactivated quickly above 55°C.

Packing:

10/20kg per Paper Carton; it is available in different types of packaging. Please contact the sales representative for more information.